PRODUCT CATALOGUE

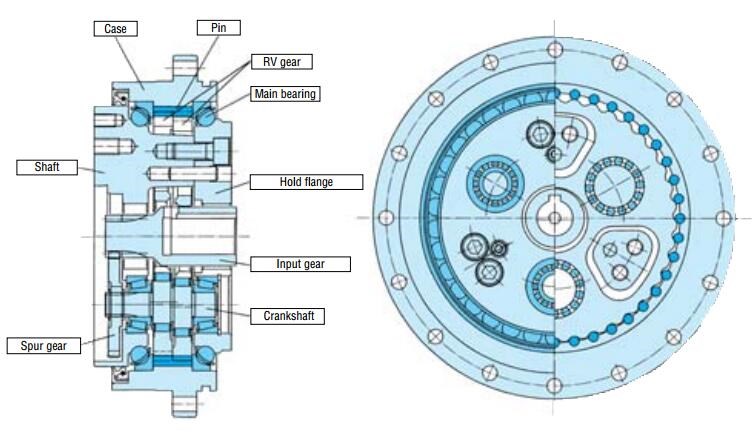

RV Reducer Bearing Structure Type

Date: 2019-03-19 17:08

RV Reducer bearing adopts non-standard size. According to the application occasions, it can be classified into main bearings and crank bearings. Main bearings include thin section angular contact ball bearing and thin section tapered roller bearing; Crank bearings include thin section tapered roller bearing, needle roller and cage assemblies.

Main Bearing

Thin Section Angular Contact Ball Bearing

Single Row Angular Contact Ball Bearing is composed of an outer ring, a inner ring, a integrated cage and a group of precision steel balls. Contact angle is 40°. Bearings can simultaneously carry radial load and one direction axial load. And also, can carry uni-directional pure axial load. This kind of bearing usually is used in pairs in back to back configuration. Small bearing section saves host machine installation space. It is mainly applied on RV Reducer main support part.

Thin Section Tapered Roller Bearing

Single Row tapered Roller Bearing is composed of an outer ring, a inner ring, a integrated cage and a group of precision steel balls. Contact angle is 20°~24°. Bearings can carry radial load and one direction axial load. And also, can carry uni-directional pure axial load. This kind of bearing usually is used in pairs. Cage uses high quality carbon constructional steel. It is mainly applied on RV Reducer main support part.

Crank Bearing

Tapered Roller Bearing

Crank Bearing structure is same with thin section tapered roller bearing. Outer dimension is smaller than thin section tapered roller bearing. It is mainly applied on crank support part.

Needle Roller and Cage Assemblies

Roller Bearing contact form is line contact. Load capacity and rigidity are higher than point contact ball bearings, which carry radial load but not axial load. Outer dimension is non-standard and combine with tapered roller bearing to use. It is mainly applied on RV Reducer support part.