PRODUCT CATALOGUE

GFI Piston Rod Guide Rings

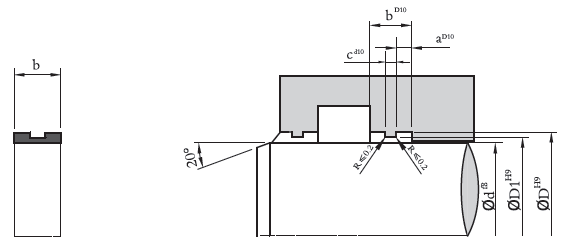

GFI Piston Rod Guide Ring

Function and UsageGFI Piston Rod Guide Ring plays a supporting and guiding role to the piston rod, which can bear high load, with low wear, and other characteristics.The special design structure makes the installation more reliable and stable. It is mainly used for heavy load condition.

Advantage

--Good pressure bearing capacity

--Inclined slice design is easy to install, and also, with high stability

--Low friction coefficient of material, long service life

Material

Filled Polyoxymethylene Delrin (POM) Our Material Code: S802

Technical Data

Working Temperature:-55℃ to +225℃ (Temperature refer to the material)

Speed: ≤1m/s

Dynamic Pressure:≤75N/mm² (60℃)

Working Medium: Mineral hydraulic oil, emulsion, water and other media

Tips: The operating limit to the load and temperature is maximum. In the actually usage, due to the interaction of work parameters the maximum must be lower.

Installation

Groove: Closed

In order to avoid the damage of the seals, during the installation, the seals should be leave away with the shape edge of the parts and tools. The sharp edges and burr in the installation area of the seal must be removed. The special design of GFI guide ring requires a high fitting surface tolerance for the components.

Example of the Order Part No. :

GFI Guide Ring

Series No.: GFI Piston Rod Diameter: d=100mm

Part Number: GFI100110S802

GFI: Series Number

100: Piston Rod Diameter

110: Groove Diameter

S802:Material Code

| GFI Piston Rod Guide Ring | ||||||

|

||||||

| d | D | D1 | b | c | a | Part No. |

| 25 | 31 | 28 | 19 | 6 | 6.5 | GFI025031 |

| 28 | 34 | 31 | 19 | 6 | 6.5 | GFI028034 |

| 30 | 36 | 33 | 19 | 6 | 6.5 | GFI030036 |

| 32 | 38 | 35 | 19 | 6 | 6.5 | GFI032038 |

| 35 | 41 | 38 | 19 | 6 | 6.5 | GFI035041 |

| 36 | 42 | 39 | 19 | 6 | 6.5 | GFI036042 |

| 40 | 46 | 43 | 19 | 6 | 6.5 | GFI040046 |

| 42 | 48 | 45 | 19 | 6 | 6.5 | GFI042048 |

| 45 | 51 | 48 | 19 | 6 | 6.5 | GFI045051 |

| 50 | 56 | 53 | 19 | 6 | 6.5 | GFI050056 |

| 55 | 61 | 58 | 19 | 6 | 6.5 | GFI055061 |

| 56 | 62 | 69 | 19 | 6 | 6.5 | GFI056062 |

| 60 | 70 | 65 | 24 | 7 | 8.5 | GFI060070 |

| 63 | 73 | 68 | 24 | 7 | 8.5 | GFI063073 |

| 65 | 75 | 70 | 24 | 7 | 8.5 | GFI065075 |

| 70 | 80 | 75 | 24 | 7 | 8.5 | GFI070080 |

| 72 | 82 | 77 | 24 | 7 | 8.5 | GFI072082 |

| 73 | 83 | 78 | 24 | 7 | 8.5 | GFI073083 |

| 75 | 85 | 80 | 24 | 7 | 8.5 | GFI075085 |

| 78 | 88 | 83 | 24 | 7 | 8.5 | GFI078088 |

| 80 | 90 | 85 | 24 | 7 | 8.5 | GFI080090 |

| 83 | 93 | 88 | 24 | 7 | 8.5 | GFI083093 |

| 85 | 95 | 90 | 24 | 7 | 8.5 | GFI085095 |

| 90 | 100 | 95 | 24 | 7 | 8.5 | GFI090100 |

| 95 | 105 | 100 | 24 | 7 | 8.5 | GFI095105 |

| 96 | 106 | 101 | 24 | 7 | 8.5 | GFI096106 |

| 100 | 106 | 103 | 19 | 6 | 6.5 | GFI100106 |

| 100 | 110 | 105 | 24 | 7 | 8.5 | GFI100110 |

| 105 | 115 | 110 | 24 | 7 | 8.5 | GFI105115 |

| 110 | 120 | 115 | 24 | 7 | 8.5 | GFI110120 |

| 115 | 125 | 120 | 24 | 7 | 8.5 | GFI115125 |

| 120 | 130 | 125 | 24 | 7 | 8.5 | GFI120130 |

| 125 | 135 | 130 | 24 | 7 | 8.5 | GFI125135 |

| 130 | 140 | 135 | 24 | 7 | 8.5 | GFI130140 |

| 140 | 150 | 145 | 24 | 7 | 8.5 | GFI140150 |

| 150 | 162 | 156 | 35 | 15 | 10 | GFI150162 |

| 155 | 167 | 161 | 35 | 15 | 10 | GFI155167 |

| 160 | 170 | 165 | 24 | 7 | 8.5 | GFI160170 |

| 160 | 172 | 166 | 35 | 15 | 10 | GFI160172 |

| 165 | 177 | 171 | 35 | 15 | 10 | GFI165177 |

| 167 | 177 | 172 | 24 | 7 | 8.5 | GFI167177 |

| 170 | 182 | 176 | 35 | 15 | 10 | GFI170182 |

| 180 | 190 | 185 | 24 | 7 | 8.5 | GFI180190 |

| 180 | 192 | 186 | 35 | 15 | 10 | GFI180192 |

| 190 | 202 | 196 | 35 | 15 | 10 | GFI190202 |

| 200 | 212 | 206 | 35 | 15 | 10 | GFI200212 |

| 220 | 232 | 226 | 35 | 15 | 10 | GFI220232 |

| 225 | 237 | 231 | 35 | 15 | 10 | GFI225237 |

| 240 | 252 | 246 | 35 | 15 | 10 | GFI240252 |

| 250 | 262 | 256 | 35 | 15 | 10 | GFI250262 |

| 260 | 272 | 266 | 35 | 15 | 10 | GFI260272 |

| 280 | 292 | 286 | 35 | 15 | 10 | GFI280292 |

| 290 | 302 | 296 | 35 | 15 | 10 | GFI290302 |

| 300 | 310 | 305 | 24 | 7 | 8.5 | GFI300310 |

| 300 | 312 | 306 | 35 | 15 | 10 | GFI300312 |

| 320 | 332 | 326 | 35 | 15 | 10 | GFI320332 |

| 350 | 362 | 356 | 35 | 15 | 10 | GFI350362 |

| 360 | 372 | 366 | 35 | 15 | 10 | GFI360372 |

| 380 | 392 | 386 | 35 | 15 | 10 | GFI380392 |

| 400 | 412 | 406 | 35 | 15 | 10 | GFI400412 |

| If any special requirements of the materials and sizes, please contact with us. | ||||||