PRODUCT CATALOGUE

KKR Piston Seals

KKR Piston Seals

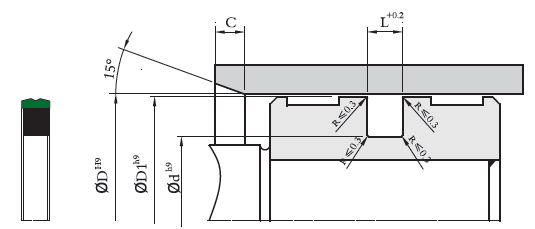

Function and UsageKKR Piston Seal is a two way combination seal which is consisted by a polyurethane slip ring and a rubber elestomer. The initial surplus of the elastomer can satisfy the sealing performance under lower pressure and static; when the pressure is increasing, the elastomer pressurizes to the polyurethane slip ring, and change the axial force of the system pressure to radial extrusion to ensure the stability of the dynamic seal; with the design of oil storage tank on the the contact surface of the slip ring, it helps to lubricate, reduced the friction, prolonged the service life of the seal. The simple design of the KKR Piston Seal is easy to install. It is suitable for standard industrial cylinder, farm equipment cylinder, light construction machinery cylinder, walking device cylinder, steering booster cylinder, and etc.

Advantage

--Good sealing effect under both dynamic and static

--Wear resistant, and long time service life

--Can by easily installed on the whole piston

--Standard components for standard mounting grooves

Material

Slip Ring Material: Polyurethane Our Material Code: P905

Elestomer Material: Nitrile Rubber (NBR) Our Material Code: N802

Combination Code: P905N

If the working condition is under low temperature, we suggest to use low temperature resistance Nitrile Rubber (NBR) for the elestomer , Our Material Code: NV705, Combination Code: P905NV

Technical Data

Working Pressure: ≤30MPa

Speed: ≤0.5m/s

Working Temperature:-30℃ to +110℃

Working Medium: Hydraulic oil, mineral hydraulic oil, water emulsion, and etc.

Tips: Limit value of the above data, can not be used at the same time. The maximum working pressure depends on the type of material, the pressure, the temperature, the gap, and etc.. In actual usage, due to the mutual influence of working parameters, the maximum value setting is lower.

Installation

Groove: Closed

In order to avoid the damage of the seals, during the installation, the seals should be leave away with the shape edge of the parts and tools. The sharp edges and burr in the installation area of the seal must be removed.

Example of the Order Part No. :

KKR Piston Seal

Series No.: KKR Cylinder Bore Diameter: d=100mm

Part Number: KKR100084P905N

KKR: Series Number

100: Cylinder Bore Diameter

084: Groove Diameter

P905N: Material Code

| KKR Piston Seals | ||||||

|

||||||

| D | d | D1 | L | C | Part No. | Remarks |

| 20 | 12.5 | 19.7 | 3.2 | 6 | KKR020012 | ○ |

| 25 | 17.5 | 24.7 | 3.2 | 6 | KKR025017 | ○ |

| 25 | 14 | 24.7 | 4.2 | 6 | KKR025014 | ○ |

| 32 | 24.5 | 31.7 | 3.2 | 6 | KKR032024 | ○ |

| 32 | 21 | 31.7 | 4.2 | 6 | KKR032021 | ○ |

| 40 | 32.5 | 39.7 | 3.2 | 6 | KKR040032 | ○ |

| 40 | 29 | 39.7 | 4.2 | 6 | KKR040029 | ○ |

| 45 | 34 | 44.7 | 4.2 | 6 | KKR045034 | ○ |

| 45 | 32 | 44.6 | 6.3 | 8 | KKR045032 | ○ |

| 50 | 39 | 49.7 | 4.2 | 8 | KKR050039 | ● |

| 50 | 34.5 | 49.6 | 6.3 | 8 | KKR050034 | ○ |

| 55 | 39.5 | 54.6 | 6.3 | 8 | KKR055039 | ○ |

| 60 | 49 | 59.7 | 4.2 | 8 | KKR060049 | ● |

| 60 | 44.5 | 59.6 | 6.3 | 8 | KKR060044 | ○ |

| 63 | 52 | 62.7 | 4.2 | 8 | KKR063052 | ○ |

| 63 | 47.5 | 62.6 | 6.3 | 8 | KKR063047 | ● |

| 63 | 50 | 65.6 | 6.3 | 8 | KKR063050 | ○ |

| 65 | 52 | 64.6 | 6.3 | 8 | KKR065052 | ○ |

| 65 | 49.5 | 64.7 | 6.3 | 8 | KKR065049 | ● |

| 70 | 59 | 69.7 | 4.2 | 8 | KKR070059 | ○ |

| 70 | 54.5 | 69.6 | 6.3 | 8 | KKR070054 | ○ |

| 70 | 57 | 69.6 | 6.3 | 8 | KKR070057 | ● |

| 75 | 59.5 | 74.6 | 6.3 | 8 | KKR075059 | ○ |

| 75 | 62 | 74.6 | 6.3 | 8 | KKR075062 | ○ |

| 80 | 69 | 79.4 | 4.2 | 8 | KKR080069 | ○ |

| 80 | 64.5 | 79.6 | 6.3 | 8 | KKR080064 | ● |

| 85 | 71.5 | 84.6 | 6.3 | 8 | KKR085071 | ○ |

| 85 | 69.5 | 84.7 | 6.3 | 10 | KKR085069 | ○ |

| 90 | 74.5 | 89.6 | 6.3 | 10 | KKR090074 | ○ |

| 90 | 69 | 89.5 | 8.1 | 10 | KKR090069 | ● |

| 90 | 69 | 89.5 | 10.5 | 10 | KKR090069A | ○ |

| 95 | 79.5 | 94.6 | 6.3 | 10 | KKR095079 | ○ |

| 100 | 84.5 | 99.6 | 6.3 | 10 | KKR100084 | ○ |

| 100 | 86.5 | 99.6 | 6.3 | 10 | KKR100086 | ○ |

| 100 | 79 | 99.5 | 8.1 | 10 | KKR100079 | ● |

| 105 | 84.5 | 104.6 | 6.3 | 10 | KKR105084 | ○ |

| 105 | 89.5 | 104.6 | 6.3 | 10 | KKR105089 | ○ |

| 110 | 89 | 109.5 | 8.1 | 10 | KKR110089 | ● |

| 115 | 94 | 114.5 | 8.1 | 10 | KKR115094 | ○ |

| 120 | 99 | 119.5 | 8.1 | 10 | KKR120099 | ● |

| 125 | 109.5 | 124.6 | 6.3 | 10 | KKR125109 | ○ |

| 125 | 104 | 124.5 | 8.1 | 10 | KKR125104 | ● |

| 140 | 119 | 139.5 | 8.1 | 10 | KKR140119 | ● |

| 160 | 139 | 159.5 | 8.1 | 10 | KKR160139 | ● |

| 180 | 159 | 179.5 | 8.1 | 10 | KKR180159 | ○ |

| 200 | 179 | 199.5 | 8.1 | 10 | KKR200179 | ● |

|

Notice: 1. “●” means the seal has existing mould; 2. “○” means no existing mould, but can provide the turning type seals. If any special requirements of the materials and sizes, please contact with us. |

||||||