PRODUCT CATALOGUE

KY Piston Seals

KY Piston Seals

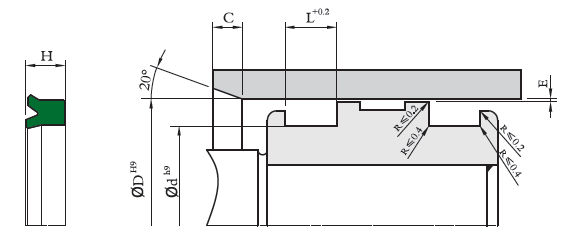

Function and UsageKY Piston Seal is a single action compact type lip seal. When it is static, the sealing effect is played by the interference compression of the two sealing lips.When it is dynamic, the system pressure is applied at the valley of the Y type seal, which increased the contact stress of the seal lip, cylinder bottom and groove bottom diameter, with the increase of pressure, the contact stress also increases correspondingly, which plays the role of dynamic sealing. KY Piston Seal is mainly used in heavy load running machinery and static pressure piston.

Advantage

--Good sealing effect, wear resistant

--Good ability to adapt the changes of the pressure

--Impact resistance, suitable for harsh conditions

-Simple design, and easy to install

--Standard components for standard mounting grooves

Material

Material: polyurethane Our Material Code: P902

Back UP Material Code: T600

If the working condition is under high pressure, we suggest to use POM for the back up, Our Material Code: S805

Technical Data

Working Pressure: ≤40MPa

Speed: ≤0.5m/s

Working Temperature:-35℃ to +110℃

Working Medium: Hydraulic oil

Clearance

| Working Pressure /MPa | 5 | 10 | 20 | 30 | 40 | |

|

Maximum Clearance E |

d<60mm | 0.40 | 0.30 | 0.20 | 0.15 | 0.10 |

| d≥60mm | 0.50 | 0.40 | 0.30 | 0.20 | 0.15 | |

Tips: Limit value of the above data, can not be used at the same time. The maximum working pressure depends on the type of material, the pressure, the temperature, the gap, and etc.. In actual usage, due to the mutual influence of working parameters, the maximum value setting is lower.

Installation

Groove: Both Closed and Opened (Open type groove is recommended for the limit diameter and limit cross section.)

In order to avoid the damage of the seals, during the installation, the seals should be leave away with the shape edge of the parts and tools. The sharp edges and burr in the installation area of the seal must be removed.

Example of the Order Part No. :

KY Piston Seal

Series No.: KY Cylinder Bore Diameter: d=100mm

Part Number: KY100080P902

KY: Series Number

100: Cylinder Bore Diameter

080: Groove Diameter

P902: Material Code

| KY Piston Seals | ||||||||

|

||||||||

| D | d | L |

L1 (with back up) |

H | C | Part No. | Back Up Part No. | Remarks |

| 16 | 8 | 6.3 | 8.3 | 5.7 | 3 | KY016008 | DF8*16*2 | ○ |

| 16 | 10 | 6.3 | 8.3 | 5.7 | 3 | KY016010 | DF10*16*2 | ○ |

| 20 | 12 | 6.3 | 8.3 | 5.7 | 3 | KY020012 | DF12*20*2 | ● |

| 24 | 16 | 6.3 | 8.3 | 5.7 | 3 | KY024016 | DF16*24*2 | ○ |

| 25 | 17 | 6.3 | 8.3 | 5.7 | 3 | KY025017 | DF17*25*2 | ○ |

| 25 | 18 | 5.6 | 7.6 | 5 | 3 | KY025018 | DF18*25*2 | ○ |

| 32 | 22 | 8 | 10 | 7.3 | 4 | KY032022 | DF22*32*2 | ● |

| 32 | 24 | 6.3 | 8.3 | 5.7 | 4 | KY032024 | DF24*32*2 | ○ |

| 35 | 25 | 8 | 10 | 7.3 | 4 | KY035025 | DF25*35*2 | ○ |

| 40 | 30 | 8 | 11 | 7.3 | 4 | KY040030A | DF30*40*3 | ○ |

| 40 | 30 | 7 | 10 | 6 | 4 | KY040030B | DF30*40*3 | ● |

| 40 | 32 | 6.3 | 8.3 | 5.7 | 4 | KY040032 | DF32*40*2 | ● |

| 45 | 35 | 7 | 10 | 6 | 4 | KY045035 | DF35*45*3 | ● |

| 50 | 40 | 8 | 11 | 7.3 | 4 | KY050040A | DF40*50*3 | ● |

| 50 | 40 | 7 | 10 | 6 | 4 | KY050040B | DF40*50*3 | ● |

| 50 | 42 | 6.3 | 8.3 | 5.7 | 4 | KY050042 | DF42*50*2 | ● |

| 55 | 45 | 7 | 10 | 6 | 4 | KY055045 | DF45*55*3 | ● |

| 56 | 41 | 12.5 | 15.5 | 11.4 | 4 | KY056041 | DF41*56*3 | ○ |

| 56 | 46 | 8 | 11 | 7.3 | 4 | KY056046 | DF46*56*3 | ● |

| 60 | 50 | 8 | 11 | 7.3 | 4 | KY060050A | DF50*60*3 | ● |

| 60 | 50 | 7 | 10 | 6 | 4 | KY060050B | DF50*60*3 | ● |

| 63 | 53 | 8 | 11 | 7.3 | 4 | KY063053A | DF53*63*3 | ● |

| 63 | 53 | 7 | 10 | 6 | 4 | KY063053B | DF53*63*3 | ● |

| 65 | 55 | 8 | 11 | 7.3 | 4 | KY065055 | DF55*65*3 | ○ |

| 70 | 60 | 13 | 16 | 12 | 4 | KY070060A | DF60*70*3 | ○ |

| 70 | 60 | 7 | 10 | 6 | 4 | KY070060B | DF60*70*3 | ● |

| 70 | 55 | 12.5 | 15.5 | 11.4 | 4 | KY070055 | DF55*70*3 | ○ |

| 75 | 63 | 9.5 | 12.5 | 8.6 | 4 | KY075063 | DF63*75*3 | ○ |

| 80 | 65 | 9.5 | 12.5 | 8.6 | 4 | KY080065A | DF65*80*3 | ● |

| 80 | 65 | 12.5 | 15.5 | 11.4 | 4 | KY080065B | DF65*80*3 | ● |

| 80 | 70 | 7.5 | 10.5 | 6.7 | 4 | KY080070A | DF70*80*3 | ● |

| 80 | 70 | 7 | 10 | 6 | 4 | KY080070B | DF70*80*3 | ● |

| 80 | 60 | 16 | 19 | 14.5 | 4 | KY080060 | DF60*80*3 | ○ |

| 90 | 75 | 12.5 | 15.5 | 11.4 | 6 | KY090075 | DF75*90*3 | ● |

| 100 | 80 | 16 | 19 | 14.5 | 6 | KY100080 | DF80*100*3 | ● |

| 100 | 85 | 12.5 | 15.5 | 11.4 | 6 | KY100085A | DF85*100*3 | ● |

| 100 | 85 | 10 | 13 | 9 | 6 | KY100085B | DF85*100*3 | ● |

| 100 | 90 | 7.5 | 10.5 | 6.7 | 6 | KY100090 | DF90*100*3 | ○ |

| 110 | 90 | 16.5 | 19.5 | 15 | 6 | KY110090A | DF90*110*3 | ● |

| 110 | 90 | 16 | 19 | 14.5 | 6 | KY110090B | DF90*110*3 | ● |

| 110 | 95 | 10 | 13 | 9 | 6 | KY110095 | DF95*110*3 | ● |

| 115 | 98 | 16 | 19 | 14.5 | 6 | KY115098 | DF98*115*3 | ○ |

| 125 | 100 | 20 | 23 | 18.2 | 6 | KY125100 | DF100*125*3 | ● |

| 125 | 105 | 16 | 19 | 14.5 | 6 | KY125105 | DF105*125*3 | ● |

| 125 | 110 | 10.6 | 13.6 | 9.6 | 6 | KY125110 | DF110*125*3 | ● |

| 130 | 110 | 16 | 19 | 14.5 | 6 | KY130110 | DF110*130*3 | ● |

| 130 | 115 | 10 | 13 | 9 | 6 | KY130115 | DF115*130*3 | ● |

| 140 | 120 | 16 | 19 | 14.5 | 6 | KY140120 | DF120*140*3 | ● |

| 140 | 125 | 10 | 13 | 9 | 6 | KY140125 | DF125*140*3 | ● |

| 140 | 115 | 20 | 23 | 18.2 | 6 | KY140115 | DF115*140*3 | ○ |

| 150 | 135 | 10 | 13 | 9 | 6 | KY150135 | DF135*150*3 | ○ |

| 160 | 135 | 20 | 23 | 18.2 | 6 | KY160135 | DF135*160*3 | ● |

| 160 | 145 | 10 | 13 | 9 | 6 | KY160145 | DF145*160*3 | ● |

| 160 | 140 | 16 | 19 | 14.5 | 6 | KY160140 | DF140*160*3 | ● |

| 170 | 155 | 10 | 14 | 9 | 6 | KY170155 | DF155*170*4 | ● |

| 180 | 155 | 20 | 24 | 18.2 | 6 | KY180155 | DF155*180*4 | ● |

| 180 | 165 | 10 | 14 | 9 | 6 | KY180160 | DF165*180*4 | ● |

| 180 | 150 | 20 | 24 | 18 | 6 | KY180150 | DF150*180*4 | ● |

| 190 | 175 | 10 | 14 | 9 | 6 | KY190175 | DF175*190*4 | ● |

| 200 | 175 | 20 | 24 | 18.2 | 7 | KY200175 | DF175*200*4 | ● |

| 200 | 185 | 10.6 | 13.6 | 9.6 | 7 | KY200185 | DF185*200*3 | ○ |

| 220 | 200 | 16.5 | 20.5 | 15 | 7 | KY220200 | DF200*220*4 | ● |

| 250 | 225 | 20 | 24 | 18.2 | 7 | KY250225 | DF225*250*4 | ● |

| 250 | 230 | 16.5 | 20.5 | 15 | 7 | KY250230 | DF230*250*4 | ○ |

| 280 | 250 | 25 | 29 | 23 | 7 | KY280250 | DF250*280*4 | ○ |

| 320 | 290 | 22 | 26 | 20 | 8 | KY320290A | DF290*320*4 | ● |

| 320 | 290 | 25 | 29 | 23 | 8 | KY320290B | DF290*320*4 | ○ |

| 350 | 320 | 23 | 27 | 21 | 8 | KY350320 | DF320*350*4 | ● |

| 360 | 330 | 25 | 29 | 23 | 8 | KY360330 | DF330*360*4 | ○ |

| 400 | 360 | 32 | 36 | 30 | 10 | KY400360 | DF360*400*4 | ○ |

| 450 | 410 | 32 | 36 | 30 | 10 | KY450410 | DF410*450*4 | ○ |

| 500 | 460 | 32 | 36 | 30 | 10 | KY500460 | DF460*500*4 | ○ |

|

Notice: 1. “●” means the seal has existing mould; 2. “○” means no existing mould, but can provide the turning type seals. If any special requirements of the materials and sizes, please contact with us. |

||||||||