PRODUCT CATALOGUE

KV Piston Seals

KV Piston Seals

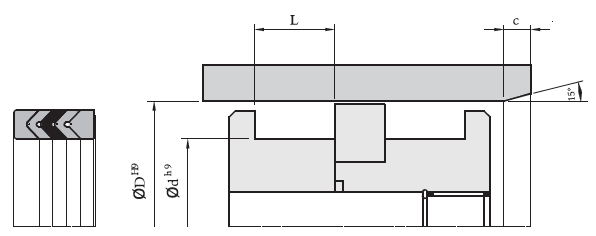

Function and UsageKV Piston Seal is combined by a set of V type rubber fabric ring, supporting ring and pressure ring. Usually it is 1+5+1 (1: pressure ring, 5: three V type rubber fabric rings and two V type rubber ring, 1: supporting ring) or 1+3+1 (1: pressure ring, 3: two type rubber fabric rings and one V type rubber ring, 1: supporting ring). In this compression type seal, the axial force exerted by the system pressure is transferred between each V type ring and the pressure is pressed on the surface of the cylinder. Because there are a number of sealing lips, so the KV Piston Seal has excellent sealing performance, compared with the monomer seal, it is not sensitive to the slight damage of the surface and the dirt in the medium. By adjusting the groove device, the best coordination of friction and sealing performance can be achieved, and the service life of the component can be effectively prolonged.

Advantage

--Refer to the different media and temperature range, can adjusted by choosing different material

-- With the stable structure, the pressure peak is not sensitive

--As the contact area is long and there are several sealing lips, so there is an excellent sealing performance

--Easy to install and replace

Material

Supporting Ring and V Type Reinforced Fabric Ring Material: Nitrile Rubber + Cloth Our Material Code: BN500

V Type Rubber Ring Material:Nitrile Rubber (NBR) Our Material Code: N800

Pressure Ring:POM Our Material Code: S801

Combination Code: BNSN

If the working condition is under high temperature or chemical resistant medium, we suggest to use FKM (Fluoro Rubber) for the V type ring, Our Material Code: F800, supporting Ring and V type rubber fabric ring we suggest to use Fabric FKM, Our Material Code: BF500. Pressure Ring we suggest to use PTFE, Our Material Code: T605. Combination Code: BFTF

Technical Data

The Standard KV Piston Seal is mainly used for plunger, piston of the press machine, cylinder, valve shaft and seal of valve spool.

Working Pressure: ≤60MPa

Speed: ≤0.5m/s

Working Temperature:-40℃ to +200℃ (Refer to the different material of the seal)

Working Medium: Mineral hydraulic oil, emulsion, water and other media

Tips: Limit value of the above data, can not be used at the same time. The maximum working pressure depends on the type of material, the pressure, the temperature, the gap, and etc.. In actual usage, due to the mutual influence of working parameters, the maximum value setting is lower.

Installation

Groove: Opened

In order to avoid the damage of the seals, during the installation, the seals should be leave away with the shape edge of the parts and tools. Each component should be installed one by one according to the order, apply grease to facilitate assembly.

Example of the Order Part No. :

KV Piston Seal

Series No.: KV Cylinder Bore Diameter: d=100mm

Part Number: KV100080BNSN

KV: Series Number

100: Cylinder Bore Diameter

080: Groove Diameter

BNSN: Material Code

| KV Piston Seals | |||||

|

|||||

| D | d | L | C | Part No. | Remarks |

| 40 | 25 | 11.5 | 7 | KV040025 | ● |

| 42 | 27 | 11.5 | 7 | KV042027 | ● |

| 45 | 30 | 11.5 | 7 | KV045030 | ● |

| 50 | 35 | 11.5 | 7 | KV050035 | ● |

| 55 | 40 | 11.5 | 7 | KV055040 | ● |

| 56 | 41 | 11.5 | 7 | KV056061 | ● |

| 60 | 45 | 11.5 | 7 | KV060045 | ● |

| 63 | 48 | 13 | 7 | KV063048 | ● |

| 70 | 50 | 15.2 | 7 | KV070050 | ● |

| 80 | 60 | 15.2 | 10 | KV080060 | ● |

| 90 | 70 | 21.2 | 10 | KV090070 | ● |

| 100 | 80 | 21.2 | 10 | KV100080 | ● |

| 110 | 90 | 21.2 | 10 | KV110090 | ● |

| 115 | 95 | 21.2 | 10 | KV115095 | ● |

| 125 | 100 | 25.8 | 10 | KV125100 | ● |

| 140 | 115 | 25.8 | 12 | KV140115 | ● |

| 150 | 120 | 29 | 12 | KV150120 | ● |

| 160 | 130 | 29 | 12 | KV160130 | ● |

| 180 | 150 | 31.5 | 12 | KV180150 | ● |

| 200 | 170 | 33.5 | 12 | KV200170 | ● |

| 225 | 195 | 33.5 | 12 | KV225195 | ● |

| 250 | 220 | 33.5 | 12 | KV250220 | ● |

| 275 | 245 | 33.5 | 12 | KV275245 | ● |

| 300 | 270 | 33.5 | 12 | KV300270 | ● |

|

Notice: 1. “●” means the seal has existing mould; 2. “○” means no existing mould, but can provide the turning type seals. If any special requirements of the materials and sizes, please contact with us. |

|||||