PRODUCT CATALOGUE

GU Rod Seals

GU Rod Seals

Function and UsageGU Rod Seal is a single action seal consisted of a U type sealing body and a V type corrosion resistant spring. which has two symmetrical sealing lips, when the pressure is low and at zero, the metal spring provide the initial preload. While the system pressure is increased, the main sealing force is formed by the system pressure, thus ensuring the reliable seal from zero pressure to high pressure.Because the seal and spring has a very good ability to adapt to the corresponding materials, it can be widely used in application such as chemical, pharmaceutical, food industry, and etc.

Advantage

--Can be used for reciprocating and rotary motion

--Anti chemical and most of the other fluid medium

--Low friction,

--Wear resistance, stable dimension

--Can adapt to the quick change of the temperature

--Can adapt to the wide range of the temperature

--Long term storage

Material

Standard usage

Sealing Body Material: Filled PTFE Our Material Code: T605

V type Spring

Technical Data

Working Pressure: Dynamic ≤20MPa Static ≤40MPa

Speed: Reciprocating ≤15m/s Rotary Motion ≤1m/s

Working Temperature:-70℃ to +260℃

Working Medium: All practical liquids, chemicals and gases

Tips: Limit value of the above data, can not be used at the same time. The maximum working pressure depends on the type of material, the pressure, the temperature, the gap, and etc.. In actual usage, due to the mutual influence of working parameters, the maximum value setting is lower.

Installation

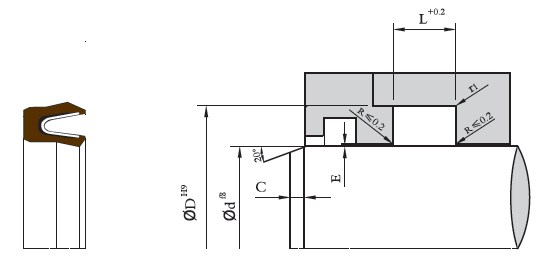

Groove: GU Rod Seal can be installed in the groove which are corresponding to MIL G 5514 and ISO3771. For a closed groove, the installation of this seal has a certain limit.

In order to avoid the damage of the seals, during the installation, the seals should be leave away with the shape edge of the parts and tools. The sharp edges and burr in the installation area of the seal must be removed.

Example of the Order Part No. :

GU Rod Seal

Series No.: GU Piston Rod Diameter: d=100mm

Part Number: GU100109T605

GU: Series Number

100: Piston Rod Diameter

109: Groove Diameter

T605: Material Code

| Installation size | ||||||||

| No. |

Cylinder Bore Diameter d |

Groove Diameter D |

Groove Width L+0.2 |

Radius R |

Maximum Clearance E |

|||

| <2MPa | <10MPa | <20MPa | <40MPa | |||||

| 1 | 3.0-9.9 | d+2.9 | 2.4 | 0.4 | 0.2 | 0.1 | 0.08 | 0.05 |

| 2 | 10.0-19.9 | d+4.5 | 3.6 | 0.4 | 0.25 | 0.15 | 0.1 | 0.07 |

| 3 | 20.0-39.9 | d+6.2 | 4.8 | 0.6 | 0.35 | 0.2 | 0.15 | 0.08 |

| 4 | 40.0-119.9 | d+9.4 | 7.1 | 0.8 | 0.5 | 0.25 | 0.2 | 0.1 |

| 5 | 120.0-630.0 | d+12.2 | 9.5 | 0.8 | 0.6 | 0.3 | 0.25 | 0.12 |

| GU Rod Seals | ||||

|

||||

| d | D | L | Part No. | Remarks |

| 3 | 5.9 | 2.4 | GU003005T605 | ○ |

| 4 | 6.9 | 2.4 | GU004006T605 | ○ |

| 5 | 7.9 | 2.4 | GU005007T605 | ○ |

| 6 | 8.9 | 2.4 | GU006008T605 | ○ |

| 8 | 10.9 | 2.4 | GU008010T605 | ○ |

| 10 | 14.5 | 3.6 | GU010014T605 | ○ |

| 12 | 16.5 | 3.6 | GU012016T605 | ○ |

| 14 | 18.5 | 3.6 | GU014018T605 | ○ |

| 15 | 19.5 | 3.6 | GU015019T605 | ○ |

| 16 | 20.5 | 3.6 | GU016020T605 | ○ |

| 18 | 22.5 | 3.6 | GU018022T605 | ○ |

| 20 | 26.2 | 4.8 | GU020026T605 | ○ |

| 22 | 28.2 | 4.8 | GU022028T605 | ○ |

| 25 | 31.2 | 4.8 | GU025031T605 | ○ |

| 28 | 34.2 | 4.8 | GU028034T605 | ○ |

| 30 | 36.2 | 4.8 | GU030036T605 | ○ |

| 32 | 38.2 | 4.8 | GU032038T605 | ○ |

| 35 | 41.2 | 4.8 | GU035041T605 | ○ |

| 36 | 42.2 | 4.8 | GU036042T605 | ○ |

| 40 | 49.4 | 7.1 | GU040049T605 | ○ |

| 42 | 51.4 | 7.1 | GU042051T605 | ○ |

| 45 | 54.4 | 7.1 | GU045054T605 | ○ |

| 48 | 57.4 | 7.1 | GU048057T605 | ○ |

| 50 | 59.4 | 7.1 | GU050059T605 | ○ |

| 52 | 61.4 | 7.1 | GU052061T605 | ○ |

| 55 | 64.4 | 7.1 | GU055064T605 | ○ |

| 56 | 65.4 | 7.1 | GU056065T605 | ○ |

| 60 | 69.4 | 7.1 | GU060069T605 | ○ |

| 63 | 72.4 | 7.1 | GU063072T605 | ○ |

| 65 | 74.4 | 7.1 | GU065074T605 | ○ |

| 70 | 79.4 | 7.1 | GU070079T605 | ○ |

| 75 | 84.4 | 7.1 | GU075084T605 | ○ |

| 80 | 89.4 | 7.1 | GU080089T605 | ○ |

| 85 | 94.4 | 7.1 | GU085094T605 | ○ |

| 90 | 99.4 | 7.1 | GU090099T605 | ○ |

| 95 | 104.4 | 7.1 | GU095104T605 | ○ |

| 100 | 109.4 | 7.1 | GU100109T605 | ○ |

| 105 | 114.4 | 7.1 | GU105114T605 | ○ |

| 110 | 119.4 | 7.1 | GU110119T605 | ○ |

| 115 | 124.4 | 7.1 | GU115124T605 | ○ |

| 120 | 132.2 | 9.5 | GU120132T605 | ○ |

| 125 | 137.2 | 9.5 | GU125137T605 | ○ |

| 130 | 142.2 | 9.5 | GU130142T605 | ○ |

| 135 | 147.2 | 9.5 | GU135147T605 | ○ |

| 140 | 152.2 | 9.5 | GU140152T605 | ○ |

| 150 | 162.2 | 9.5 | GU150162T605 | ○ |

| 160 | 172.2 | 9.5 | GU160172T605 | ○ |

| 170 | 182.2 | 9.5 | GU170182T605 | ○ |

| 180 | 192.2 | 9.5 | GU180192T605 | ○ |

| 190 | 202.2 | 9.5 | GU190202T605 | ○ |

| 200 | 212.2 | 9.5 | GU200212T605 | ○ |

| 210 | 222.2 | 9.5 | GU210222T605 | ○ |

| 220 | 232.2 | 9.5 | GU220232T605 | ○ |

| 230 | 242.2 | 9.5 | GU230242T605 | ○ |

| 240 | 252.2 | 9.5 | GU240252T605 | ○ |

| 250 | 262.2 | 9.5 | GU250262T605 | ○ |

| 280 | 292.2 | 9.5 | GU280292T605 | ○ |

| 300 | 312.2 | 9.5 | GU300312T605 | ○ |

| 320 | 332.2 | 9.5 | GU320332T605 | ○ |

| 350 | 362.2 | 9.5 | GU350362T605 | ○ |

| 360 | 372.2 | 9.5 | GU360372T605 | ○ |

| 400 | 412.2 | 9.5 | GU400412T605 | ○ |

|

Notice:“○” can be customized. If any special requirements of the materials and sizes, please contact with us. |

||||