PRODUCT CATALOGUE

GZG Rotary Seals

GZG Rotary Seal

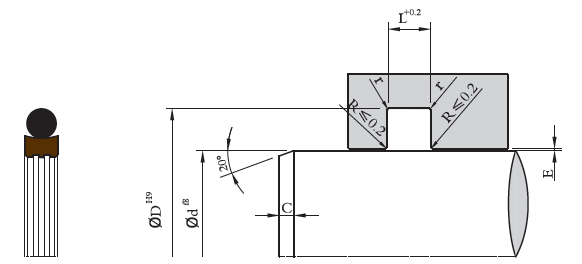

Function and UsageGZG Rotary Seal is composed of a high wear resistance, low friction filled PTFE slip ring, and a rubber o ring. The O ring provides preload, compensate to the wear of the slip ring. At the same time,, according to the slip ring section size, processing one or two annular grooves in the sealing surface to form a lubricating oil cavity, further reduces the friction force, enhances the sealing surface specific pressure, achieves the good sealing effect. The standard GZG rotary seals are used to the sealing condition which do have rotate or swing rods, shafts, pins, swivel joints, and etc.

Advantage

--Small frictional force

--Start no creep, no stick

--Wear resistance, good dimensional stability

--Simple trench, easy to install

--With a lubrication chamber

Material

Slip Ring Material: Filled PTFE Our Material Code: T605

Elastomer Material: Nitrile Rubber (NBR) Our Material Code: N800

Combination Code: T605N

If the working condition is under high temperature or chemical resistant medium, we suggest to use FKM for the elestomer , Our Material Code: F800. Combination Code: T605F

If the working condition is under low temperature, we suggest to use low temperature resistance Nitrile Rubber (NBR) for the elestomer , Our Material Code: NV705, Combination Code: T605NV

Technical Data

Working Pressure: ≤40MPa

Speed: ≤2m/s

Working Temperature: Nitrile Rubber (NBR) -30℃ to +120℃

FKM -20℃ to +200℃

When the working temperature is greater than 60℃, the continuous working pressure must be reduced.

Working Medium: Hydraulic oil, emulsion, water, air, and etc.

Tips: Limit value of the above data, can not be used at the same time. The maximum working pressure depends on the type of material, the pressure, the temperature, the gap, and etc.. In actual usage, due to the mutual influence of working parameters, the maximum value setting is lower.

Installation

Groove: Both Closed and Opened (Open type groove is recommended for the limit diameter and limit cross section.)

In order to avoid the damage of the seals, during the installation, the seals should be leave away with the shape edge of the parts and tools. The sharp edges and burr in the installation area of the seal must be removed.

Example of the Order Part No. :

GZG Rotary Seal

Series No.:GZG Piston Rod Diameter: d=100mm

Part Number: GZG10004T605N

GZG : Series Number

100: Piston Rod Diameter

04: Groove Diameter

T605N: Material Code

| Series No. |

O Ring CS (mm) |

Recommended Standard Piston Rod Diameter Range d(mm) |

Groove Diameter D(mm) |

Groove Width L(mm) |

Chamfer radius r |

Maximum Clearance E(mm) | ||

| ≥ | ≤ | 25MPa | 40MPa | |||||

| GZG | 1.8 | 10 | 18 | d+4.9 | 2.2 | 0.4 | 0.15 | 0.1 |

| 2.65 | 19 | 37 | d+7.5 | 3.2 | 0.6 | 0.15 | 0.1 | |

| 3.55 | 38 | 199 | d+11 | 4.2 | 1.0 | 0.15 | 0.1 | |

| 5.3 | 200 | 255 | d+15.5 | 6.3 | 1.3 | 0.15 | 0.1 | |

| 7 | 256 | 649 | d+21 | 8.1 | 1.6 | 0.25 | 0.2 | |

| GZG Rotary Seal | ||||

|

||||

| d | D | L | C | Part No. |

| 10 | 14.9 | 2.2 | 3 | GZG01002 |

| 12 | 16.9 | 2.2 | 3 | GZG01202 |

| 15 | 19.9 | 2.2 | 3 | GZG01502 |

| 16 | 20.9 | 2.2 | 3 | GZG01602 |

| 18 | 22.9 | 2.2 | 3 | GZG01802 |

| 20 | 27.5 | 3.2 | 3 | GZG02003 |

| 22 | 29.5 | 3.2 | 3 | GZG02203 |

| 25 | 32.5 | 3.2 | 3 | GZG02503 |

| 28 | 35.5 | 3.2 | 3 | GZG02803 |

| 30 | 37.5 | 3.2 | 3 | GZG03003 |

| 32 | 39.5 | 3.2 | 3 | GZG03203 |

| 36 | 43.5 | 3.2 | 3 | GZG03603 |

| 38 | 49 | 4.2 | 6 | GZG03804 |

| 40 | 51 | 4.2 | 6 | GZG04004 |

| 42 | 53 | 4.2 | 6 | GZG04204 |

| 45 | 56 | 4.2 | 6 | GZG04504 |

| 48 | 59 | 4.2 | 6 | GZG04804 |

| 50 | 61 | 4.2 | 6 | GZG05004 |

| 52 | 63 | 4.2 | 6 | GZG05204 |

| 55 | 66 | 4.2 | 6 | GZG05504 |

| 56 | 67 | 4.2 | 6 | GZG05604 |

| 60 | 71 | 4.2 | 6 | GZG06004 |

| 63 | 74 | 4.2 | 6 | GZG06304 |

| 70 | 81 | 4.2 | 6 | GZG07004 |

| 75 | 86 | 4.2 | 6 | GZG07504 |

| 80 | 91 | 4.2 | 6 | GZG08004 |

| 85 | 96 | 4.2 | 6 | GZG08504 |

| 90 | 101 | 4.2 | 6 | GZG09004 |

| 95 | 106 | 4.2 | 6 | GZG09504 |

| 100 | 111 | 4.2 | 6 | GZG10004 |

| 105 | 116 | 4.2 | 6 | GZG10504 |

| 110 | 121 | 4.2 | 6 | GZG11004 |

| 115 | 126 | 4.2 | 6 | GZG11504 |

| 120 | 131 | 4.2 | 6 | GZG12004 |

| 125 | 136 | 4.2 | 6 | GZG12504 |

| 130 | 141 | 4.2 | 6 | GZG13004 |

| 135 | 146 | 4.2 | 6 | GZG12504 |

| 140 | 151 | 4.2 | 6 | GZG14004 |

| 150 | 161 | 4.2 | 6 | GZG15004 |

| 160 | 171 | 4.2 | 6 | GZG16004 |

| 170 | 181 | 4.2 | 6 | GZG17004 |

| 180 | 191 | 4.2 | 6 | GZG18004 |

| 190 | 201 | 4.2 | 6 | GZG19004 |

| 200 | 215.5 | 6.3 | 6 | GZG20006 |

| 210 | 225.5 | 6.3 | 8 | GZG21006 |

| 220 | 235.5 | 6.3 | 8 | GZG22006 |

| 240 | 255.5 | 6.3 | 8 | GZG24006 |

| 250 | 265.5 | 6.3 | 8 | GZG25006 |

| 260 | 281 | 8.1 | 8 | GZG26008 |

| 270 | 291 | 8.1 | 12 | GZG27008 |

| 280 | 301 | 8.1 | 12 | GZG28008 |

| 300 | 321 | 8.1 | 12 | GZG30008 |

| 320 | 341 | 8.1 | 12 | GZG32008 |

| 350 | 371 | 8.1 | 12 | GZG35008 |

| 360 | 381 | 8.1 | 12 | GZG36008 |

| If any special requirements of the materials and sizes, please contact with us. | ||||